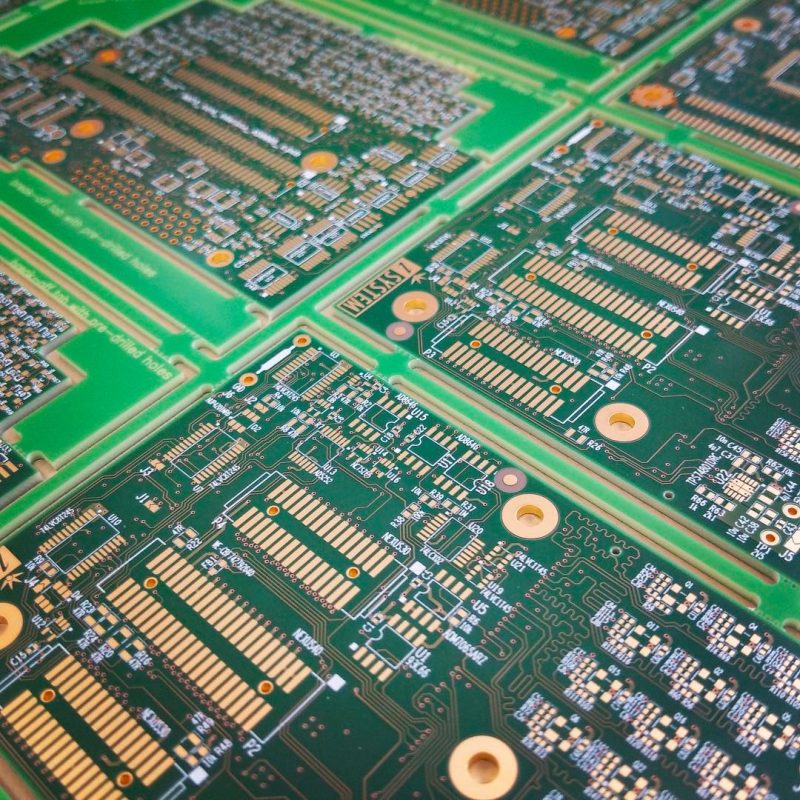

PCB Contact Manufacturing Capability

Full range of PCB manufacturing and assembly services to fit all your printed circuit board capability needs.

PCB Contact has introduced world-class PCB production equipment and high-precision testing equipment. We adopted a scientific management model to form a strong and leading process manufacturing capability.

- 1 to 16 layers of PCB boards,

- a minimum aperture of 0.1mm,

- a minimum line width,

- minimum trace width/space 0.075mm,

- Line gap 0.075mm,

- 0.4mm BGA Pitch

All are available in our processing. PCB Contact can design and process special processes such as controlled depth milling, half-hole, mixed pressure, and so on.

Capabilities in Manufacturing HDI PCB

PCB Contact is a professional PCB manufacturer that can produce high-quality HDI PCB products. Check our PCB manufacturing capabilities in the following table:

| Item | Capability |

| Material | CEM-3, FR-4(Normal to High Tg), High CTI FR-4, Polyimide(PI), Aluminum Base, Rogers |

| Surface finish | HAL, HASL Leadfree, ENIG, Chem Tin, OSP, Gold Finger, Immersion Silver, ENEPIG |

| Min. Core thickness | 4mil/0.1mm |

| Prepreg type | 1080, 2116, 7628, 106, 3313, 2165, 1500 |

| Max board size | 24.41X47.24inch/620X1200mm |

| Copper thickness | Min. base copper 1/3Oz Max. base copper 10Oz |

| Min. hole size | Mechanical drilling: 0.2mm |

| Laser drilling: 0.075mm | |

| Min. spacing | Line to line: 0.075mm/3mil |

| Line to pad: 0.125mm/5mil | |

| Pad to pad: 0.125mm/5mil | |

| Hole to hole: 0.3mm/12mil | |

| Line to hole: 0.2mm/8mil | |

| Pad to hole: 0.2mm/8mil | |

| SMD to hole: 0.3mm/12mil | |

| Via to via: 0.3mm/12mil | |

| Min. line width | Inner layer: 0.075mm/3mil |

| Outer layer: 0.075mm/3mil | |

| BGA area: 0.075mm/3mil | |

| Special design: 0.065mm/2.5mil | |

| HDI design: 0.05mm/2mil | |

| Min. annular ring | Through hole: 0.125mm/5mil |

| Blind/Buried via: 0.1mm/4mil | |

| Micro via: 0.075mm/3mil | |

| Board thickness | Min: 0.2mm/8mil |

| Max: 7.0mm/276mil | |

| Aspect ratio | Standard: 8:1 |

| Max: 12:1 | |

| Impedance control | Tolerance: ±10% |

| Testing: TDR method | |

| Solder mask | Min. width: 0.075mm/3mil |

| Min. spacing: 0.075mm/3mil | |

| Legend | Min. width: 0.15mm/6mil |

| Min. height: 0.8mm/31mil | |

| Peelable mask | Min. width: 0.8mm/31mil |

| Min. spacing: 0.8mm/31mil | |

| Carbon printing | Min. width: 0.5mm/20mil |

| Min. spacing: 0.5mm/20mil |

PCB Delivery Lead Times

|

Area

Layer

|

<1㎡ | 1㎡≤S<3 | 3㎡≤S<5㎡ | Fast |

|---|---|---|---|---|

| 2L | 4day | 6day | 7day | 1day |

| 4L | 6day | 7day | 8day | 2day |

| 6L | 6day | 7day | 9day | 2day |

| 8L | 7day | 9day | 9day | 3day |

| 10L | 9day | 10day | 13day | 5day |

Highest Standard and Certifications

We are certified to ISO9001 & 14001, IATF16949, SA08000, QC08000, ISO13485, UL certification. All surface mount boards go through a solder paste inspection machine and a 3D automated optical inspection machine for solder joints and part orientation. You can count on us to meet your needs, from the simplest boards to the most complex designs for small & medium scale production.

PCB Manufacturing & Testing Equipment

Industry-leading PCB precision manufacturing production equipment and college quality inspection equipment from PCB Contact allows us to expand our possibilities beyond the most complicated solutions in manufacturing and meet time to market expectations to our customers. From High Mix/Low volume to mass production quantities capability allows us to meet on time delivery and cost saving solution.

Our Product Case Recommendation

Industry-leading PCB precision manufacturing production equipment and college quality inspection equipment from PCB Contact allows us to expand our possibilities beyond the most complicated solutions in manufacturing and meet time-to-market expectations to our customers. From high mix/low volume to mass production quantities capability allows us to meet on time delivery and cost saving solutions.

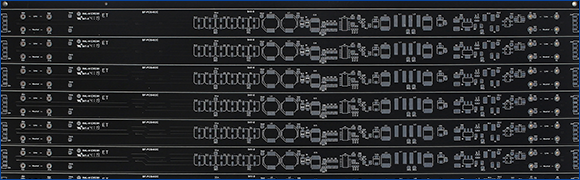

Long Board With 1200mm

- Monthly capability: 5000 Sq M/Month

- Layer: 6 Layers

- Material: FR4 TG170

- Finished board thickness: 1.6mm

- Dimension: 50.56mm*1200mm

- Finished copper thickness: 1 oz

- Surface finishing: LF HAL

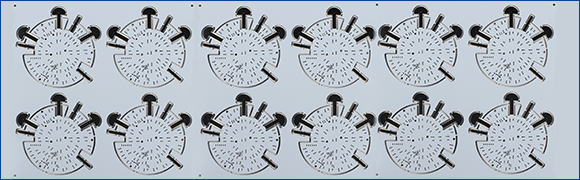

Depth-control Board

- Monthly capability: 2200 Sq M/Month

- Layer: Double Side

- Material: FR4 TG150

- Dimension: 256.46mm*251.94mm

- Finished board thickness: 1.55mm

- Finished copper thickness: 2oz

- Surface finishing: HAL

Heavy Copper Board

- Monthy Capability: 3500 Sq M/Month

- Layer: 4 Layers

- Material: FR4 TG170

- Dimension: 350.56mm*580mm

- Finished board thickness: 2.3mm

- Outer layer Finished copper thickness: 6 oz

- Inner layer base copper thickness: 6 oz

- Surface finishing: LF HAL